ETH Zurich’s Impact Printing: A Breakthrough in Sustainable Construction

ETH Zurich’s Impact Printing: A Breakthrough in Sustainable Construction

The innovative team at ETH Zurich is making waves in the construction world with their new method, Impact Printing. This groundbreaking technique utilizes Earth-based materials, such as sand, silt, clay, and gravel, to construct environmentally friendly structures. As detailed in their publication in Springer Nature, Impact Printing promises to be a greener and more cost-effective alternative to traditional 3D printing methods.

ETH Zurich’s research team, guided by Lauren Vasey, a prominent SNSF Bridge Fellow, has developed a method to turn materials excavated from construction sites into usable building products. By avoiding cement and opting for locally-sourced materials, they achieve significantly lower carbon emissions. Impressively, the materials used in Impact Printing require minimal additives, cutting the need for cement and enhancing sustainability.

This process involves a robotic tool that, guided by a digital blueprint, applies Earth-based material layers at high speeds, creating robust structures without needing chemical stabilizers. Despite using a small percentage of mineral stabilizers, the ETH Zurich team aims to eliminate these for a fully recyclable construction method.

The research indicates that structures built using Impact Printing can support substantial weight from the start, offering advantages in structural integrity and environmental impact. Using this technology, the team has successfully erected walls up to 6.5 feet tall, showcasing the method’s practicality in real-world applications.

Beyond ETH Zurich, a global wave of research is similarly focused on sustainable construction practices. For example, the University of Virginia is developing a sustainable concrete alternative using graphene and limestone-calcined clay, showing significant environmental benefits. Meanwhile, Berlin’s TU and Brunel University are enhancing 3D printing concrete by incorporating recycled materials, revealing steps toward more sustainable construction.

The ultimate vision involves developing a prefabrication facility to bring Impact Printing technology to the market, bridging the gap between innovative research and practical construction solutions. If successful, it could significantly transform the industry, presenting a viable alternative to current 3D printing methods, reducing the environmental footprint and offering more sustainable urban development solutions.

More Articles

Getting licensed or staying ahead in your career can be a journey—but it doesn’t have to be overwhelming. Grab your favorite coffee or tea, take a moment to relax, and browse through our articles. Whether you’re just starting out or renewing your expertise, we’ve got tips, insights, and advice to keep you moving forward. Here’s to your success—one sip and one step at a time!

Top Tech Upgrades Consumers Anticipate in 2025

Advanced Integration of Artificial Intelligence

Artificial Intelligence (AI) is set to be a cornerstone of consumer technology in **2025**. As AI becomes more integrated into everyday devices, it will usher in an era of personalized convenience. AI-powered systems are expected to learn and adapt to user habits, offering a seamless and connected experience. From smart home devices to personal assistants, AI will play a pivotal role in making daily tasks more efficient and enjoyable. For more on AI’s influence, consider reading about its impact on the 2024 US elections.Upgradation of 5G Connectivity

The rollout of 5G technology is set to revolutionize user interaction with devices and the Internet. With its promise of ultra-fast speeds and low latency, **5G** will enhance everything from streaming high-definition content to online gaming. Beyond entertainment, **5G** will significantly impact industries such as telemedicine and remote work, facilitating seamless virtual experiences.AR Experiences

Augmented Reality (AR) is expected to integrate smoothly into daily life by **2025**, transforming sectors like retail, education, and entertainment. **AR** will redefine shopping experiences by allowing users to visualize products in their own environments. In education, **AR** will make learning more interactive and accessible. For further exploration, see how **AR** is utilized beyond gaming in business and education.Wearable Health Technology

Wearable technology has become essential for health monitoring. As we move forward, consumers will demand more than just tracking; they will look for actionable insights and preventive healthcare solutions. Devices will offer personalized health recommendations, shifting the focus from reactive to proactive well-being management. Discover key features of smartwatches here.Sustainable Tech Solutions

With growing environmental awareness, there is a rising demand for eco-friendly technology. Products made from sustainable materials and designed to reduce carbon footprints are becoming increasingly popular. This shift towards green technology aligns with consumers’ values for sustainability.Smart Home Automation

The demand for smart home technology is set to soar, driven by the desire for integrated automation solutions. From smart thermostats to security systems, consumers want a unified ecosystem that offers convenience and safety. The advanced security features in smart homes are becoming the standard for safe living.Blockchain Technology Beyond Cryptocurrency

Blockchain technology is expanding beyond its roots in cryptocurrency, offering enhanced security and transparency in areas like supply chain and healthcare record management. By **2025**, **blockchain** will play a significant role in ensuring safe and traceable transactions, reflecting a broader cultural shift towards digital responsibility.Conclusion

As technology continues to weave itself into the fabric of our daily lives, **2025** promises to be a landmark year for consumer innovation. The convergence of personalization, connectivity, sustainability, and intuitive design will push companies to meet the sophisticated demands of modern consumers. Stay updated with the latest developments by joining our WhatsApp Channel.China Leads the Charge in Sustainable Housing with “Green and Healthy Housing” Initiative

Extending its innovative reach beyond its own borders, China is exporting prefabricated structures such as hotels, hospitals, student dormitories, and social housing. These structures are built to near-completion in Chinese factories and shipped globally in containers, allowing for efficient and sustainable assembly at their destinations. This strategy not only supports China’s domestic eco-efforts but also aids international communities in their pursuit of sustainable building solutions.

At the heart of this green initiative is a real estate development firm established in 2007. Known for its dedication to green technology and social responsibility, the firm has been recognized with numerous awards and has invested millions in charitable activities. Its core values—“Honesty, Trustworthiness, Dedication, and Professionalism”—highlight its commitment to continuous improvement and environmental stewardship.

In contrast to traditional construction methods, prefabricated green buildings offer a quicker and more cost-effective production process. They generate less waste and consume significantly less energy, prompting a growing number of global hotels, including luxury resorts, to adopt these Chinese prefabricated green structures. Departing from the boxy, utilitarian designs of the past, these modern buildings showcase sophisticated aesthetics that blend seamlessly with diverse global landscapes.

One of the production hubs for these green housing units features a unique Museum of Windows and Doors, likely the only one of its kind worldwide, surrounded by expansive factory grounds. Visitors can observe the meticulous design and technological sophistication that characterize these eco-friendly prefabrications, with production facilities spanning areas comparable to small countries.

In addition to exporting green buildings, China is also sharing knowledge on sustainable design and construction practices through academic partnerships, particularly with universities. By offering courses on project management and building assembly, China is empowering future developers and architects worldwide to apply sustainable methods using materials sourced from China. This educational component aims to enable international developers to work independently and promote sustainable practices locally, thereby avoiding potential disruptions to local construction industries.

By reducing energy and material waste, prefabricated green buildings can significantly decrease the global hospitality and tourism industry’s ecological footprint. Often, discussions around tourism sustainability focus on reducing operational emissions, such as those from flights or transportation, while overlooking the environmental impact of infrastructure development. China’s green housing initiative brings attention to this crucial aspect, providing a scalable model for eco-conscious construction.

Moreover, recent diplomatic developments between China and India, including the resolution of a longstanding border conflict, signal improved cooperation that could further enhance the reach of green construction. For instance, India might soon open its airspace for international flights linked to the Chinese-funded airport in Pokhara, Nepal, enhancing regional connectivity and supporting sustainable tourism.

China’s green housing model exemplifies how eco-innovation can not only meet pressing climate goals but also influence industries worldwide. As this sustainable construction model gains traction globally, the world moves one step closer to a greener, more efficient, and environmentally friendly future in housing and beyond.

Read the full article on Travel And Tour World.

The DeFi Revolution: Reshaping Finance

The DeFi Revolution: Reshaping Finance

The rise of blockchain technology is fundamentally transforming the financial landscape, ushering in a new era of Decentralized Finance (DeFi). This is not just a passing trend but a significant leap in how financial services will be delivered and accessed in the future. DeFi enables peer-to-peer financial interactions without intermediaries, challenging the very foundations of traditional banking systems.From Bitcoin to Ethereum: A New Financial Frontier

Since the introduction of Bitcoin in 2008, blockchain technology has evolved significantly. The launch of Ethereum in 2015, with its smart contract capabilities, opened up new possibilities in finance. This paved the way for platforms like Aave, MakerDAO, Compound, and Uniswap to disrupt traditional financial systems, offering decentralized alternatives for lending, borrowing, and trading.As of 2024, the Total Value Locked (TVL) in DeFi protocols is approximately $54 billion, indicating a growing trend where conventional financial institutions must engage with this disruptive technology.

Convergence of Traditional and Decentralized Finance

Initially, financial institutions approached blockchain with caution, maintaining a clear separation from the crypto space. However, consumer demand has led to a hybrid integration, blending digital and traditional financial services. DeFi’s systemic capabilities, such as enhanced accessibility, transparency, and efficiency, are becoming increasingly appealing.Unlike traditional banking systems that often exclude individuals due to insufficient credit history or geographical barriers, DeFi provides open access to anyone with internet connectivity. Moreover, DeFi’s transparent operations stand in stark contrast to the opaque practices of traditional banks.

Impact on Lending and Payments Markets

In the lending market, DeFi’s rapid growth is evident. Although it constitutes less than 1% of global household debt, DeFi’s impact is profound, prompting traditional institutions to reassess their risk assessment and underwriting models. DeFi offers unique lending models outside conventional broker channels, providing higher yields and improved accessibility.The payments sector is also undergoing transformation. Traditional cross-border settlements often involve lengthy procedural bottlenecks, especially during weekends and holidays. Cryptocurrencies facilitate quicker transactions, and global payment networks like Visa and Mastercard are exploring stablecoin settlements, hinting at a reshaped payments landscape.

New Investment Instruments and Strategies

The rise of cryptocurrency exchange-traded products (ETPs) and ETFs introduces new investment opportunities. With around 900 products listed globally, amounting to nearly $10 billion, these instruments make digital assets more accessible to traditional investors. Institutional involvement in crypto investments substantiates the mainstream status cryptocurrencies are acquiring.Tokenization of assets represents another trend, enabling digital ownership of physical assets such as gold and real estate, facilitating fractional ownership and enhanced liquidity. This nascent development is drawing interest from individual and corporate investors alike.

The Future of Finance

Looking forward, DeFi has the potential to dramatically change the way financial services are delivered. While it might not entirely replace traditional banking, DeFi could help enhance transparency, efficiency, and inclusiveness within the industry. The article suggests a potential convergence between decentralized and mainstream financial models, offering a cooperative future in finance.The original article was authored by Svyatoslav Garal, Global Head of Payments at Wirex, a fintech leader with extensive experience in banking, payments, and crypto industries. “`

Revolutionizing Healthcare: The Rise of Wearable Technologies

Revolutionizing Healthcare: The Rise of Wearable Technologies

In a world where technology continues to redefine the boundaries of healthcare, wearable health technologies are making waves, offering patients the ability to monitor their health from the comfort of their homes. According to a recent Forbes article, these innovations are enhancing patient monitoring and providing real-time data, leading to improved health outcomes for both patients and providers.

In a world where technology continues to redefine the boundaries of healthcare, wearable health technologies are making waves, offering patients the ability to monitor their health from the comfort of their homes. According to a recent Forbes article, these innovations are enhancing patient monitoring and providing real-time data, leading to improved health outcomes for both patients and providers.

The Power of Continuous Monitoring

One of the most significant advancements in wearable technology is the continuous vital sign collection. Devices equipped with advanced sensors are now capable of providing real-time data on patients’ health, ensuring timely intervention and personalized care. As highlighted by Frank Chan from Medtronic, this constant monitoring minimizes gaps in observation, empowering clinicians to offer proactive support.Microfluidic Patches: A Breakthrough in Remote Care

Microfluidic patches, as noted by Amitkumar Shrivastava of Fujitsu, are small adhesive patches that provide real-time analysis of bodily biomarkers. This innovation reduces the need for invasive tests, enhances diagnostic accuracy, and improves patient engagement, setting a new standard in remote healthcare.Wearable ECGs and Smartwatches

Wearable ECG devices, including smartwatches, have transformed cardiac care by enabling remote monitoring of heart activity. Konstantin Klyagin of Redwerk explains how these devices, paired with apps, allow physicians to review data remotely, promoting proactive health management and early detection of stroke risks.AI and Wearables: A Perfect Partnership

The integration of AI in wearable devices is driving incredible progress in patient monitoring. Jeff Wong from EY emphasizes that AI processes vast amounts of biometric data rapidly, resulting in prescriptive, preventive care and reducing costs for healthcare providers.Hyper-Personalized Health Technology

Hyper-personalization, powered by AI and machine learning, is transforming user experiences in wearable health technology. Deepak Gupta of Cars24 Financial Services highlights how these systems offer tailored recommendations, motivating users to make healthier choices and achieve superior health outcomes.As we continue to navigate the future of healthcare, these wearable technologies are not just innovations; they are a revolution in how we perceive and manage health. For more insights, visit the Forbes Technology Council.

U.S. Precision Medicine Market Set to Triple by 2033

U.S. Precision Medicine Market Set to Triple by 2033

A recent study has unveiled a promising trajectory for the U.S. precision medicine market, projected to expand from USD 24.95 billion in 2023 to a staggering USD 76.12 billion by 2033. This growth, driven by a compound annual growth rate (CAGR) of 11.80% from 2024 to 2033, underscores the transformative potential of healthcare tailored to individual genetic, environmental, and lifestyle factors.

Precision Medicine: A Tailored Approach

Precision medicine is revolutionizing healthcare by offering individualized treatment plans. This approach is particularly impactful in oncology, where molecular testing allows oncologists to customize cancer therapies, enhancing patient outcomes while reducing adverse effects. The FDA plays a crucial role in regulating Next Generation Sequencing (NGS) tests, which are vital for generating comprehensive patient data.

Collaborative Efforts and Regulatory Support

The strategic collaboration between the FDA, laboratories, and academic institutions has led to the development of a flexible regulatory framework, essential for fostering innovation in NGS technology. The Precision Medicine Initiative, spearheaded by the NIH, aims to integrate genetics and lifestyle factors into disease prevention and treatment. This initiative is part of a broader effort to incorporate precision medicine across all healthcare sectors, highlighted by the ambitious All of Us Research Program.

Market Trends and Innovations

The precision medicine market is segmented into various categories, with drug discovery and oncology leading the technology and application segments, respectively. The pharmaceutical sector is the dominant end-user, while single-molecule real-time sequencing emerges as a frontrunner in sequencing technology.

Recent trends include the application of advanced precision medicine technologies to enhance healthcare outcomes and address treatment accessibility. Noteworthy developments, such as Google’s AI-driven drug discovery initiatives, exemplify the sector’s dynamic evolution. Collaborations, like GSK’s partnership with Tempus, further highlight precision medicine’s escalating role in research and development.

Financial Barriers and Opportunities

Despite the promising growth, financial barriers remain, particularly in cancer care, where high treatment costs can limit accessibility. However, the rapid adoption of precision medicine offers new opportunities for healthcare evolution, empowering tailored patient care and fostering innovation in therapeutic development.

The global precision medicine market is also anticipated to grow significantly, from USD 91.72 billion in 2024 to USD 246.30 billion by 2033, with North America capturing a substantial share of the market. This reinforces the region’s pivotal role in advancing the industry.

Conclusion

As the U.S. precision medicine market continues to expand, it promises to reshape the healthcare landscape, offering more personalized and effective treatment options. The collaborative efforts of regulatory bodies, industry stakeholders, and research institutions will be crucial in overcoming challenges and unlocking the full potential of precision medicine.

The Future of Cybersecurity: Resilience’s Predictions for 2025

Dr. Ann Irvine, Resilience’s chief data scientist, foresees a major **cyber incident** involving a relatively unknown company. She likens the potential impact to the CDK Global incident from this past summer, emphasizing the profound ripple effects that smaller, less-visible organizations can have on broader networks and industries. Moreover, she anticipates a successful **deepfake attack** targeting a **Fortune 500 company**, a testament to the evolving sophistication of **cyber threats**. However, Dr. Irvine dismisses the likelihood of a nationwide **internet outage**, citing the strong disincentives for threat actors who risk severe repercussions.

Public awareness of **cybersecurity** is expected to play a crucial role in shaping future policies and practices. Dr. Irvine highlights the growing consciousness among individuals and organizations, noting that the **insurance industry** will increasingly drive accountability by linking financial incentives to improved **cybersecurity measures**.

Justin Shattuck, Resilience’s chief information security officer, echoes these concerns while emphasizing the evolving role of corporate leadership in combating **cyber threats**. He predicts a significant industry-wide push to tighten contract language between companies and their vendors. This shift will see nebulous terms like “should” replaced with binding phrases like “shall,” ensuring clearer expectations and responsibilities.

Shattuck also points to alarming trends in **ransomware**, with financial damages soaring by 411% recently. He expects this upward trajectory to continue, driven by advancing attacker strategies and rising ransom demands. Furthermore, the visibility of **CISOs** in corporate leadership roles is anticipated to increase, empowering them to influence strategic risk management decisions at the board level. Companies with emboldened and empowered **CISOs** will likely fare better in preventing and mitigating the effects of **cyberattacks**.

For a more detailed exploration of these predictions, you can read the original article on Insurance Business America.

Revolutionizing Healthcare: NHS Trials AI Tool for Early Diabetes Detection

Revolutionizing Healthcare: NHS Trials AI Tool for Early Diabetes Detection

In an unprecedented leap for preventive medicine, the National Health Service (NHS) in England is poised to trial Aire-DM, a groundbreaking AI tool designed to predict the risk of type 2 diabetes a remarkable 13 years before its onset. This ambitious trial is set to commence in 2025 at both Imperial College Healthcare NHS Trust and Chelsea and Westminster Hospital NHS Foundation Trust, marking a significant stride in healthcare innovation.

How Aire-DM Works

Aire-DM utilizes advanced AI algorithms to scrutinize electrocardiogram (ECG) readings obtained during routine heart scans. By detecting subtle changes in the heart’s electrical signals—often invisible to the human eye—this technology provides an early warning system for potential type 2 diabetes development. These changes, such as prolonged electrical activation times, are crucial indicators of how diabetes can affect cardiac structure and function. Dr. Libor Pastika, a clinical research training fellow at Imperial College, underscores the transformative potential of Aire-DM, stating, “AI holds enormous potential to transform care, leading to substantial health improvements. By unlocking insights hidden within ECG data, Aire-DM could revolutionize how we predict and manage the future risk of type 2 diabetes.”Importance of Early Detection

Type 2 diabetes, a chronic condition affecting millions globally, can lead to severe complications such as heart disease, kidney failure, and neuropathy. Early detection allows healthcare providers to implement preventive measures, including dietary changes, increased physical activity, and medication, to delay or even prevent the disease’s onset. Traditional methods of identifying diabetes risk often rely on family history, blood sugar levels, and lifestyle factors. However, Aire-DM’s ability to analyze ECG data offers a more precise and proactive approach.

Traditional methods of identifying diabetes risk often rely on family history, blood sugar levels, and lifestyle factors. However, Aire-DM’s ability to analyze ECG data offers a more precise and proactive approach.

Global Implications and Future Prospects

As the first healthcare system globally to implement trials for this AI-based tool, the NHS aims to assess its accuracy, feasibility, and impact on patient outcomes. If successful, Aire-DM could become a standard screening tool in hospitals and clinics worldwide, setting a precedent for future AI applications in medicine. Its success could spur advancements in predicting other chronic conditions, reimagining the future of preventive care. The trial of Aire-DM by the NHS signifies a monumental leap forward in preventive medicine. By leveraging AI to detect diabetes risk early, healthcare providers can intervene sooner, ultimately saving lives and reducing the long-term impact of the disease. As the trial unfolds, it holds the promise of setting a global precedent for integrating AI into routine healthcare, revolutionizing how chronic conditions like type 2 diabetes are managed and prevented. “`Revolutionizing Skin Cancer Diagnosis with AI: Efficacy and Future Prospects

AI’s Role in Revolutionizing Skin Cancer Diagnosis

In a groundbreaking study published by Nature on May 14, 2024, researchers have delved into the burgeoning field of artificial intelligence (AI) in dermatology. The systematic review and meta-analysis focus on AI’s efficacy compared to human clinicians in diagnosing skin cancer, a disease that remains the most common neoplasm worldwide.

AI vs. Clinicians: A Comparative Analysis

The study highlights a comprehensive comparison between AI algorithms and human clinicians, including experienced dermatologists and general practitioners. It reveals that AI can match or even surpass specialists in accuracy, particularly in categorizing skin lesions as benign or malignant. This finding underscores AI’s potential to transform dermatological practices by enhancing diagnostic precision.

Augmented Intelligence in Medical Practices

One of the study’s pivotal insights is the concept of ‘augmented intelligence,’ where AI is integrated into medical practices to assist clinicians. This approach is especially beneficial for generalists and non-specialist clinicians, bolstering their diagnostic capabilities. The study suggests that AI’s collaboration with human expertise can lead to improved diagnostic outcomes, particularly in primary care settings.

Broader Trends in Healthcare

The increasing use of AI in dermatology mirrors a broader trend of incorporating advanced technologies in healthcare to enhance diagnostic accuracy. The structured research approach, using systematic reviews and meta-analyses, consolidates evidence from various studies, providing a quantitative assessment of AI’s capabilities in clinical scenarios.

References and Further Reading

For those interested in further exploring the topic, the original article references key studies such as Lakhani et al.’s work on skin cancer screening, Wu et al.’s systematic review on deep learning in skin cancer classification, and Jones et al.’s review of AI and machine learning algorithms for early skin cancer detection. These studies are accessible through their respective publications:

- Lakhani, N. A. et al. (2014)

- Wu, Y. et al. (2022)

- Jones, O. T. et al. (2022)

- Sangers, T. E. et al. (2023)

Conclusion

This study marks a significant step towards embracing AI in clinical settings, with the potential to revolutionize how skin cancer is diagnosed and managed. It calls for further real-world studies and randomized clinical trials to fully realize AI’s benefits in healthcare.

The Dawn of Personalized Medicine: AI’s Transformative Role in Healthcare

The Dawn of Personalized Medicine: AI’s Transformative Role in Healthcare

In a world where the promise of personalized medicine is finally being realized, Erez Meltzer, CEO & Board Member of Nanox, stands at the forefront of this revolution. With over 35 years of experience leading global companies, Meltzer is witnessing firsthand how artificial intelligence (AI) is reshaping patient care, moving beyond mere incremental improvements to offer truly individualized healthcare at scale.

While the concept of personalized medicine is not new, its effective implementation has been hampered by the complexity of human biology and the sheer volume of data involved. Here, AI emerges as a game-changer, providing the computational power and analytical prowess needed to process this complexity and extract actionable insights. As AI continues to learn from the vast amounts of healthcare data, its accuracy and predictive capabilities grow exponentially, enhancing its ability to personalize care.

Revolutionizing Diagnostics and Early Detection

AI is making significant strides in diagnostics and early detection. Advanced algorithms, particularly deep learning models, are analyzing medical imaging data with unprecedented accuracy and speed. These AI systems augment, rather than replace, radiologists, enabling more precise and efficient diagnoses and the ability to quickly identify incidental findings in scans.

The true power of AI in diagnostics lies in its ability to personalize the process. By considering individual risk factors, AI can tailor screening schedules, ensuring high-risk patients receive more frequent screenings while reducing unnecessary procedures for low-risk individuals. This approach not only improves patient outcomes but also optimizes healthcare resources.

Predictive Analytics: A New Frontier in Preventive Care

The potential of AI in predictive analytics is vast. By integrating data from various sources—including electronic health records, genetic information, and lifestyle data—AI models can predict individual patient risks with unprecedented accuracy. For instance, researchers at the University of Virginia have developed an AI model for predicting outcomes in heart failure patients, enabling healthcare providers to tailor their interventions accordingly.

Moreover, models like the pancreatic cancer risk model from MIT’s Computer Science & Artificial Intelligence Laboratory have the potential to expand early screening benefits from 10% to 35% of patients. By identifying individual risk factors early, we can develop personalized strategies to manage these risks, potentially reducing the burden of chronic diseases and improving overall health outcomes.

Personalizing Treatment Plans

AI’s impact extends well into the treatment phase. AI-assisted treatment planning is emerging as a powerful tool for clinicians, allowing for more personalized and effective care strategies. A team at Northwestern University’s McGaw Medical Center is creating a model to predict long-term outcomes for breast cancer patients, aiming to recategorize patients for shorter, less intense treatment plans with fewer side effects.

Addressing Challenges and Ethical Considerations

Despite AI’s massive potential in healthcare, key challenges remain. Integrating AI requires buy-in from various stakeholders, from overloaded IT departments to hesitant doctors. Furthermore, the risk of bias in AI models, if not trained on diverse datasets, can exacerbate existing healthcare disparities. Ensuring fairness and equity in AI-driven healthcare is both an ethical and practical necessity.

As we increasingly rely on AI for healthcare decisions, addressing these challenges is paramount. Ensuring the integrity and adaptability of AI algorithms, mitigating biases, and preserving the human element in healthcare remain essential priorities.

The Path Forward

Looking ahead, AI has the potential to revolutionize healthcare by enabling personalization across the entire patient journey. However, AI should support, not replace, healthcare professionals. As we continue to develop AI technologies, we must do so responsibly, focusing on improving patient outcomes and maintaining trust. By embracing these technologies ethically, we can create a healthcare system that truly centers on the individual patient.

The AI revolution in healthcare is well underway, and as industry leaders, it is our responsibility to guide this transformation. The potential benefits—lives improved and saved—are too significant to ignore.

DeFi: Revolutionizing the Financial Landscape

DeFi: Revolutionizing the Financial Landscape

In a compelling exploration of the financial landscape, Himanshu Kumar, CEO of AMBCrypto, delves into the transformative potential of Decentralized Finance (DeFi) and its implications for traditional banking. Highlighting DeFi’s revolutionary approach, Kumar discusses how the democratization of financial services through blockchain technology is reshaping access, breaking down barriers, and challenging established institutions.DeFi allows for peer-to-peer transactions by removing intermediaries, facilitated by smart contracts that automate agreements without requiring a third party. This not only enhances efficiency but also reduces costs, ultimately making financial services more accessible to a broader audience. The impact on financial inclusion is significant, providing 1.7 billion unbanked individuals with services via a smartphone and internet connection, thus spurring economic growth and empowerment.

Transparency and Trust

Transparency, a core feature of DeFi, is achieved through every transaction being recorded on a public ledger. This transparency builds trust among users by allowing them to verify transactions, reducing the risk of fraud and corruption, and holding platforms accountable.Despite these advancements, challenges remain, particularly in the realm of regulation and security. Kumar stresses the importance of working with regulators to create clear guidelines that protect consumers while allowing innovation to thrive. He also emphasizes the necessity for stringent security measures to foster user confidence in DeFi platforms.

Adapting to Change

The article further discusses the potential for traditional banks to adapt by collaborating with DeFi platforms, which could lead to the development of innovative products and services. It touches upon the need for simplifying user interfaces and educating the public to encourage wider adoption of DeFi.Finally, environmental considerations are acknowledged, calling for a shift towards energy-efficient solutions within the blockchain realm to ensure sustainable growth. Under Kumar’s leadership, AMBCrypto aims to bridge the gap between technology and the public, empowering readers with accurate news and insightful analysis.

In summary, DeFi is not just a trend but a transformative force impacting the future of finance. As Himanshu Kumar aptly states, it opens doors to a more inclusive and transparent financial world.

Revolutionizing Healthcare: Telemedicine Services in 2024

Revolutionizing Healthcare: Telemedicine Services in 2024

As the landscape of healthcare continues to transform, telemedicine has emerged as a pivotal solution for those seeking medical guidance and prescription services from the comfort of their homes. In 2024, telemedicine services have expanded not only in availability but also in the variety of offerings tailored to meet diverse patient needs and preferences. In a recent CNET article, a comprehensive guide was provided on the best telemedicine services, helping individuals select the most suitable option for their healthcare needs.

Sesame Care: Affordable and Transparent

Sesame Care offers a straightforward approach to primary care, mental health consultations, and prescription refills, all while maintaining transparency in pricing. Although it operates out of network with insurance companies, its services remain relatively affordable, making healthcare accessible for budget-conscious individuals.

HealthTap: Continuity in Care

HealthTap distinguishes itself by fostering a strong doctor-patient relationship, allowing patients to retain the same physician for future consultations. Offering services across primary care and chronic condition management, HealthTap is ideal for those seeking continuity in their healthcare journey.Hims & Hers: Privacy and Convenience

Hims & Hers specializes in personal care, particularly in areas that might traditionally be stigmatized, such as sexual wellness and mental health. While it does not accept insurance, the convenience of home delivery in discreet packaging makes it a solid choice for privacy-conscious individuals.Dr. B: Accessible Care for All

Dr. B diverges from the norm with its pay-what-you-can model, offering services even if patients cannot afford the flat consultation fee. This approach makes healthcare accessible to a broader audience, although the range of services may not be as extensive as other providers.MDLive: Insurance-Friendly Telehealth

MDLive provides mental health and urgent care services and is compatible with major insurance providers. It’s a solid pick for those looking to leverage their health insurance for telehealth visits. These are just a few of the notable highlights from CNET’s list, which also explores options like PlushCare, Doctor on Demand, and others, each offering unique features and benefits tailored to different aspects of healthcare. For further details and to learn more about these services, visit the full article on CNET.Revolutionizing Neurology: The AI Frontier

Revolutionizing Neurology: The AI Frontier

In a groundbreaking exploration of artificial intelligence’s (AI) transformative potential, a recent article published by Frontiers delves into how AI is reshaping the landscape of neurological care, particularly in emergency settings.

The Promise of AI in Neurology

AI technologies are being harnessed to revolutionize the diagnosis and management of neurological disorders. By integrating AI into various stages of patient care—from imaging diagnostics to personalized treatment plans—healthcare providers are witnessing a new era of medical innovation. According to the article, AI’s role in diagnostic imaging is particularly noteworthy, offering enhanced accuracy and speed in identifying conditions like stroke and traumatic brain injury.Advancements and Challenges

The article highlights recent advancements in AI applications within neurology, underscoring the potential for improved patient outcomes. However, the integration of AI into clinical practice is not without challenges. Ethical considerations, such as data privacy and algorithmic bias, pose significant hurdles. Moreover, practical barriers, including the need for infrastructure investment and clinician training, must be addressed to fully realize AI’s potential.Future Directions

Looking ahead, the article outlines prospective research areas and emerging trends in AI-assisted neurology. It suggests a focus on developing multimodal AI frameworks that combine imaging, genetic information, and clinical biomarkers for more comprehensive diagnoses. Additionally, the integration of AI with wearable devices and telemedicine platforms could offer continuous monitoring and real-time alerts, enhancing patient care.Recommendations for Clinical Practice

To facilitate the adoption of AI technologies in neurology, the article recommends several strategies:- Investing in infrastructure

- Improving data quality and diversity

- Fostering interdisciplinary collaboration

- Ensuring ethical and regulatory compliance

- Supporting ongoing research and development

This comprehensive review underscores AI’s potential to revolutionize neurological care, offering new hope for patients while emphasizing the need for responsible and equitable implementation.

Public Perception of Genetic Engineering: Insights Before and After the CRISPR Era

Public Perception of Genetic Engineering: Insights Before and After the CRISPR Era

The introduction of CRISPR-Cas9 in 2012 was a groundbreaking moment in the field of genetics, offering a more accessible method for precise genome modifications. This advancement has not only transformed genetic research but also ignited debates on the ethical implications of modifying human and animal genomes. There’s been a surge in both scientific and public interest, leading to extensive studies aimed at gauging public opinion on genetic engineering.A recent systematic review sheds light on the evolving public perceptions towards genetic modification both before and after CRISPR-Cas9’s debut. Conducted over a span of 35 years, the review chronicled public attitudes in various regions, including Asia, Europe, and North America, through an in-depth examination of questionnaire surveys. You can access the original study for more details here.

Before CRISPR, public discussions largely revolved around the potential medical applications of genetic engineering in humans, such as gene therapies aimed at curing genetic diseases. Conversely, the idea of genetic enhancement in humans was met with skepticism and often outright rejection. The public’s concern centered on ethical considerations, such as the naturalness of altering the human genome and potential societal impacts.

Post-CRISPR, while the overall acceptance of genome editing for treating diseases has increased, attitudes remain mixed regarding non-therapeutic enhancements. The differentiation between therapeutic and non-therapeutic uses remains significant; there’s strong support for treating severe genetic conditions but hesitance and ethical reservations persist regarding enhancements, such as altering intelligence or physical attributes.

The stance on genetically modifying animals similarly hinges on intended use—medical applications, such as producing organs for transplantation, receive higher acceptance compared to the use of genetic changes for food production.

The relationship between public awareness and attitude is complex. Generally, better-informed individuals tend to show greater support for genetic technologies, although this correlation is sometimes weak.

This comprehensive review also highlights methodological aspects of the surveys included, underscoring the need for standardized approaches to ensure consistency across future studies.

As genetic engineering technologies like CRISPR continue to advance, public consultation will be crucial, especially as these applications may directly impact everyday lives. This review underscores the importance of inclusive dialogue and informed policy-making to align technological innovation with societal values and expectations.

For more detailed insights, the original study and its supplementary materials offer further context and understanding of this evolving landscape.

Revolutionizing Real Estate: The Impact of IoT

Understanding the Impact of IoT on Real Estate

**IoT technology** is not just a buzzword; it’s a transformative force in real estate. With over 15 billion **IoT devices** currently in use, a number expected to reach 29 billion by 2030, the potential for innovation is immense. The Statista report highlights this explosive growth, emphasizing the increasing reliance on interconnected devices to enhance convenience, efficiency, and security in both residential and commercial properties.

The Business Benefits of IoT

The adoption of **IoT in real estate** brings numerous advantages. It offers cost efficiency by optimizing energy management systems, thereby reducing utility expenses. This not only provides affordable housing solutions but also addresses the pressing need for eco-friendly homes. According to CNBC, the U.S. faces a shortage of over 5 million affordable homes, and **IoT** could be key in bridging this gap.Moreover, **IoT** enhances incident management and safety. With smart sensors, potential hazards like fires or leaks can be detected early, ensuring swift response and minimizing damage. This proactive approach to safety is vital in today’s fast-paced world.

Environmental Sustainability and Innovation

**IoT’s role** in promoting environmental sustainability cannot be overstated. By enabling efficient resource consumption, **IoT** helps reduce the ecological footprint of buildings, catering to the growing demand for green homes. Additionally, innovative applications like virtual home hunting and smart decision-making tools are reshaping the real estate landscape, offering immersive experiences to potential buyers.

Real-World Examples of IoT in Action

Several companies are leading the charge in **IoT integration**. Samsung’s SmartThings Station, Eve Systems’ Matter-compatible accessories, and Shelly’s smart home automation devices are just a few examples of how **IoT** is being woven into the fabric of modern living. These innovations highlight the growing trend towards smarter, more connected homes.The collaboration between Latch and Honeywell, as well as Schneider Electric’s Easy Homes, further exemplifies the real-world application of **IoT** in enhancing property management and user experience.

Looking Ahead

As the **real estate sector** continues to embrace **IoT**, the potential for further innovation is boundless. With an anticipated market value of $2.5 trillion by 2029, according to the IoT Market Report, the integration of **IoT in real estate** promises to redefine how we live and work. The future is indeed bright for **smart homes** and **IoT-enabled real estate**.Key Property Investment Trends to Watch in 2025

Smaller Cities on the Rise

The dominance of major urban centers like New York and San Francisco is waning. According to Hajji, **smaller cities** such as Boise, Charlotte, and Tampa are experiencing rapid growth due to the shift towards **remote work**. This trend presents lucrative opportunities for investors seeking higher returns outside the traditional hotspots.Demand for Green Buildings

**Sustainability** is becoming a cornerstone of property investment. **Eco-friendly buildings**, which reduce energy consumption and environmental impact, are increasingly sought after. The Home Innovation Blog highlights the growing preference for sustainable homes, a trend echoed by government incentives for **green construction**.The Renting Revolution

With home prices continuing to rise, as noted in the Goldman Sachs Insights, **renting** is becoming more prevalent, especially among younger generations. **Build-to-rent (BTR) communities** are gaining traction, offering investors steady rental income and appealing amenities for tenants.Technological Transformations

The integration of **technology into property management** is revolutionizing the industry. **AI and automation** streamline operations, while **blockchain** enhances transaction security. Embracing these innovations can provide investors with a competitive edge.Interest Rates and Inflation

**Interest rates and inflation** remain critical factors in real estate investment. As borrowing costs rise, the market may slow, but real estate continues to be a robust hedge against inflation. Keeping a close watch on these economic indicators is crucial for making informed investment decisions.Opportunities in Affordable Housing

The demand for **affordable housing** is intensifying, with governments offering incentives for developments in this sector. **Public-private partnerships** are emerging as a solution to the housing crisis, presenting investors with a chance to achieve strong returns while contributing to social welfare.Conclusion

Navigating the property market in 2025 requires keen awareness of these evolving trends. Investors who adapt to changes in market dynamics, prioritize sustainability, and leverage technology will be well-positioned for success. As Johan Hajji emphasizes, staying ahead of the curve is essential for maximizing returns in this competitive environment.CMS Unveils Limited Digital Health Policies in Final Medicare Rule

CMS Reveals Limited Digital Health Policies in Final Medicare Rule

In a move that has drawn considerable attention just days before the 2024 presidential election, the **Centers for Medicare & Medicaid Services (CMS)** has released the final calendar year 2025 physician fee schedule (PFS) rule. This rule, which impacts **digital therapeutics**, **telehealth**, **rural health clinics**, and **opioid treatment programs**, underscores CMS’s limited authority in shaping digital health payment policies.

Digital Health Policies

CMS has finalized several digital health policies, as initially proposed in July’s draft rule. However, the offerings remain modest. New codes have been introduced for **digital therapeutics**, particularly aimed at mental healthcare. These changes mainly involve redefining existing codes to distinguish them from remote therapeutic monitoring codes. CMS’s authority in this area is limited, prompting a call for congressional action to create a new benefit category for digital therapeutics.

Telehealth Policies

With the expiration of **Medicare telehealth flexibilities** looming at the end of 2024, CMS has highlighted the necessity for Congress to extend key telehealth waivers. These waivers have significantly expanded telehealth services since 2020. Permanent coverage for audio-only visits and direct supervision via telehealth has been confirmed, yet geographical and origin site restrictions continue to pose challenges. For further details, you can refer to the original article.

Rural Health Clinics and Federally Qualified Health Centers

CMS has been striving to achieve payment parity for telehealth services compared to in-person services in **rural health clinics** and **federally qualified health centers**. While a special payment rate is applied for telehealth, CMS has opted to retain its current payment methodology for now, though reforms may be considered in the future.

Opioid Treatment Programs

The rule acknowledges the importance of telehealth in **opioid treatment programs**, especially for older Medicare beneficiaries who rely heavily on audio-only services. CMS will allow telehealth usage for periodic assessments, marking a step forward in addressing opioid use disorder through digital means.

For a comprehensive understanding of the finalized rule and its implications, visit the CMS Federal Register.

Conclusion

While CMS has made some progress, the agency emphasizes the need for congressional action to broaden and secure these developments. The future of **digital health policies** remains uncertain, with much depending on legislative support.

KBank’s Crypto Dilemma: Navigating Legislative Changes Amid IPO Plans

The financial landscape in South Korea is poised for a seismic shift as KBank, a major digital bank, grapples with a legislative curveball. The bank, which is heavily reliant on deposits from Upbit, Korea’s dominant cryptocurrency exchange, is facing a potential profit squeeze. The new Virtual Asset User Protection Act, set to take effect on July 19, 2024, mandates that banks must pay interest on crypto exchange deposits, a move that could severely impact KBank’s bottom line.

Currently, Upbit client deposits constitute a substantial 5 trillion won, approximately $3.6 billion, which is over 20% of KBank’s total client balances. While this figure reflects a decrease from previous levels, the impending requirement to pay interest could almost nullify the bank’s profits. The anticipated interest rate stands at 1%, a significant increase from the current 0.1% KBank pays. This change could necessitate an expenditure of around 50 billion won ($36 million), a figure alarmingly close to the bank’s profit margins.

The timing of this legislative change poses a particular challenge for KBank as it readies itself for an initial public offering (IPO). The potential financial strain from interest payments on crypto deposits might devalue the bank, complicating its IPO ambitions.

Bank Dependence on the Crypto Sector

KBank’s situation is reminiscent of Silvergate Bank in 2023, which faced a similar predicament due to its reliance on the crypto sector. Silvergate eventually opted for a voluntary shutdown after experiencing mass withdrawals post-crypto crash, despite having plans to repay all depositors. Similarly, Signature Bank, which had some exposure to the crypto industry, also faced collapse, although management denied that cryptocurrency was the cause.

In South Korea, no other bank shares KBank’s level of exposure to cryptocurrency exchange deposits, making its situation unique. As the banking sector braces for the implications of this new law, KBank stands at a crossroads, navigating the fine line between innovation and financial stability.

The Transformation of Healthcare: AI’s Role in Diagnostics and Personalized Medicine

From Data to Diagnosis

AI’s ability to analyze vast amounts of data is paving the way for a profound change in medical diagnostics. Khosla predicted that AI could take over up to 80% of standard medical tasks, reducing errors and biases in human diagnosis. This is particularly evident in fields like radiology and pathology, where AI’s proficiency in analyzing medical imaging allows for the early detection of diseases such as cancer, significantly improving treatment outcomes.

Moreover, AI’s integration into diagnostics is advancing global healthcare equity. By deploying AI-driven tools in under-resourced areas, high-quality diagnostics become accessible where specialized medical professionals are scarce, thus democratizing healthcare.

Personalized Medicine: Tailoring Treatment with AI

AI’s role in personalized medicine is among its most promising applications. By analyzing genetic profiles and real-time health data, AI enables treatments tailored to individual patients. This shift from a one-size-fits-all approach to personalized care reduces adverse reactions and enhances treatment effectiveness. Research in Nature Humanities and Social Sciences Communications highlights AI’s role in driving precision healthcare, where treatments are increasingly customized based on biological markers, environmental factors, and lifestyle choices.

Additionally, AI is accelerating drug development. Pharmaceutical companies are leveraging AI to analyze large datasets from clinical trials, identifying potential new drug candidates more quickly and accurately than traditional methods. This faster drug discovery process could lead to more effective treatments reaching patients sooner, potentially transforming disease management and care.

AI in Patient Care Management

AI’s potential in patient care management is substantial. By continuously monitoring patient health data, AI systems can predict potential health issues and provide timely interventions, shifting healthcare from a reactive model to a proactive one. This proactive approach not only improves patient outcomes but also reduces long-term healthcare costs. AI-driven patient care management enables continuous monitoring, allowing healthcare providers to anticipate issues before they become critical.

AI-powered predictive analytics also play a crucial role in preventive care, identifying patients at risk of developing conditions like diabetes or hypertension long before symptoms appear. This early intervention strategy can prevent the onset of these diseases, significantly reducing the burden of chronic illnesses, which are among the leading causes of death worldwide.

Ethical Considerations and Challenges

Integrating AI into healthcare is not without challenges, particularly concerning privacy, security, and ethics. AI systems require vast data to function effectively, raising concerns about data breaches and privacy. As AI systems make more autonomous decisions, ethical questions arise, such as who is responsible for incorrect diagnoses or treatment recommendations made by AI. These are complex issues that healthcare providers and regulators must address as AI becomes more prevalent in the industry (IQVIA).

The Nature article also underscores the ethical implications of AI in healthcare beyond data privacy and decision-making. AI’s use in patient care could lead to the dehumanization of healthcare, where decisions may become overly data-driven, potentially overlooking the nuances of human empathy and judgment. Balancing AI’s efficiency with the need for a human touch in patient care will be critical in the coming years.

Integrating AI

For healthcare leaders eager to embrace AI, a strategic, phased approach is recommended. Begin by identifying specific areas where AI can deliver immediate value, such as diagnostics or patient management, and launch pilot projects to test and refine these tools. It’s essential to build a multidisciplinary team that includes clinicians, data scientists, and ethicists to ensure that AI solutions are both effective and ethically sound. By focusing on small, manageable projects, AI implementation can be gradually scaled while minimizing disruption.

Equally important is addressing privacy, security, and ethical concerns upfront. Leaders should establish strong data governance frameworks to protect patient information and ensure transparency in how AI systems are used. Engaging with patients and stakeholders about the benefits and safeguards of AI is crucial for maintaining trust. Successfully integrating AI and enhancing patient care while upholding the values of compassion and ethics hinges on a culture of innovation and continuous learning.

A New Era of Healthcare

The future of healthcare lies in the seamless integration of AI technologies as partners in care, not just tools. AI is set to reshape healthcare by improving outcomes, reducing costs, and enabling personalized care. While the journey toward AI-driven healthcare is still in its early stages, the impact of these technologies is already being felt. As AI continues to advance, it will redefine the relationship between patients and healthcare providers, making care more efficient, effective, and personalized.

The Geography of Pandemic-Era Home Price Trends and Implications for Affordability

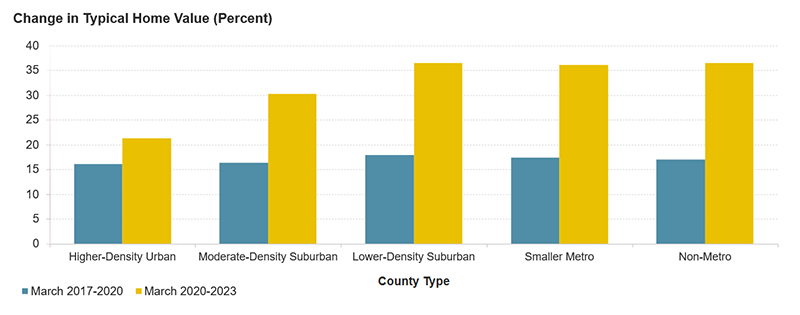

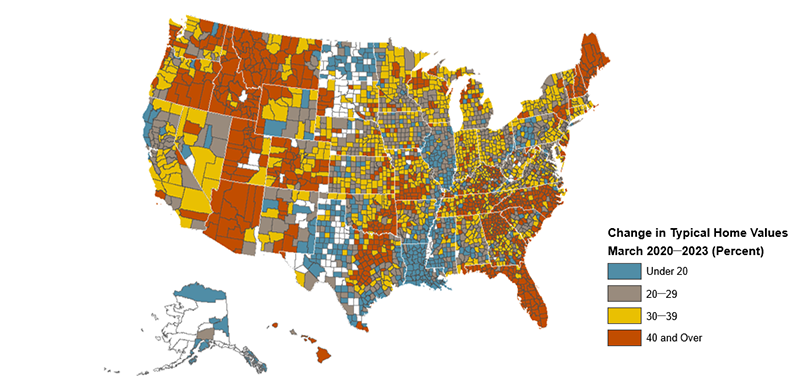

However, this growth was anything but uniform. A compelling new paper titled “The Geography of Pandemic-Era Home Price Trends and the Implications for Affordability” from the Harvard Joint Center for Housing Studies reveals that rural and low-density areas experienced the most significant price increases. The shift toward remote work allowed families to explore housing options beyond high-cost urban centers, leading to a migration trend towards more affordable, less populated regions.

In particular, low-density suburbs of large cities, smaller markets, and rural areas witnessed a notable 36 percent increase in home prices, mirroring the national trend. In contrast, urban and moderate-density suburbs within large metropolitan areas—those with populations exceeding one million—saw more modest increases of 30 percent and 21 percent, respectively. This represents a marked departure from pre-pandemic patterns when price growth was more evenly spread across different regions.

Rural Areas: A Case of Dramatic Growth

The disparity in growth is further highlighted by the fact that typical home values in 31 percent of non-metro counties surged by at least 40 percent following the pandemic. By comparison, only 18 percent of urban counties experienced growth beyond this threshold. Such disproportionate growth has intensified affordability issues, particularly in non-metro regions where the average home-value-to-income ratio has escalated from 2.5 to 3.9, approaching levels previously seen in urban counties before the pandemic.

The disparity in growth is further highlighted by the fact that typical home values in 31 percent of non-metro counties surged by at least 40 percent following the pandemic. By comparison, only 18 percent of urban counties experienced growth beyond this threshold. Such disproportionate growth has intensified affordability issues, particularly in non-metro regions where the average home-value-to-income ratio has escalated from 2.5 to 3.9, approaching levels previously seen in urban counties before the pandemic.

Affordability Challenges Intensify

The rapid increase in home prices has significantly strained affordability in areas that were once considered more cost-effective. Rising interest rates have further compounded these affordability challenges, making homeownership an increasingly elusive goal for many. Whether these trends will persist depends on several factors, including ongoing remote work dynamics, regional affordability differences, and the capacity of housing supplies to meet new demand.

The rapid increase in home prices has significantly strained affordability in areas that were once considered more cost-effective. Rising interest rates have further compounded these affordability challenges, making homeownership an increasingly elusive goal for many. Whether these trends will persist depends on several factors, including ongoing remote work dynamics, regional affordability differences, and the capacity of housing supplies to meet new demand.

The original article on this topic can be found here.

AI in Healthcare: Transforming the Industry Today and Tomorrow

AI in Healthcare: Transforming the Industry Today and Tomorrow

In a world where technology is rapidly evolving, artificial intelligence (AI) is proving to be a game-changer in the healthcare sector. Once considered experimental, AI-powered tools are now making significant strides in improving patient outcomes, enhancing operational efficiency, and reducing costs. These advancements are not just theoretical; they are reshaping the very fabric of healthcare delivery. AI Tools Delivering Value Today

The impact of AI is evident across various facets of healthcare:

AI Tools Delivering Value Today

The impact of AI is evident across various facets of healthcare:

- Diagnostics: AI algorithms are enhancing diagnostic accuracy and efficiency. For instance, Google Cloud Healthcare is improving diagnostic speed and accuracy, while the AI-powered Butterfly Network’s handheld ultrasound device offers accessible point-of-care imaging.

- Drug Discovery: AI is accelerating drug development. Companies like Insilico Medicine use AI to identify promising drug candidates much faster than traditional methods.

- Personalized Medicine: AI-driven algorithms analyze patient data to craft personalized treatment plans. Tempus Labs leverages AI to provide tailored cancer treatments by analyzing genomic data.

- Remote Patient Monitoring: AI-enabled devices enhance chronic condition management. Livongo Health uses AI to monitor glucose levels and offer personalized coaching for diabetes management.

- Predictive Analytics: Health systems like Kaiser Permanente and Mayo Clinic employ AI-powered analytics to identify high-risk patients and prevent hospital readmissions.

- Administrative Efficiency: AI streamlines administrative tasks. Platforms like Cedar automate patient billing, while AI-powered chatbots improve patient engagement and communication.

- Predictive Healthcare: Advanced AI models will enable predictive healthcare, potentially predicting events like heart attacks days before they occur.

- Natural Language Processing for Clinical Documentation: AI will automate the transcription and summarization of medical records, unlocking insights from unstructured patient data.

- AI-Driven Telehealth: Integrating AI-powered diagnostic tools will enhance telehealth platforms, allowing for remote monitoring and early interventions.

- AI-Assisted Robotic Surgery: The integration of AI in robotic surgery will provide surgeons with real-time data analysis, optimizing surgical techniques and reducing recovery times.

- Precision Medicine and Gene Editing: AI-assisted technologies like CRISPR will enable targeted treatments for genetic diseases.

- Data Privacy and Security: Balancing privacy with utility is critical as AI systems require vast amounts of sensitive health data.

- Integration with Legacy Systems: Many healthcare providers operate on outdated infrastructure, complicating AI integration.

- Regulatory Approval: Regulatory bodies are still developing frameworks for AI in healthcare, which may slow adoption.

- Ethical Considerations: The “black box” nature of AI decision-making raises ethical concerns, especially in critical patient care decisions.

- Trust and Adoption: Building trust in AI-driven decisions is essential for widespread adoption by healthcare providers and patients.

- Healthcare Organizations: Start small with high-impact areas, invest in data infrastructure, and develop an AI roadmap.

- Healthcare Professionals: Embrace continuous learning, participate in AI pilot projects, and focus on AI-human collaboration.

- Patients: Stay informed about AI tools, ask questions about AI-driven care, and responsibly share data to improve AI healthcare tools.

Revolutionizing Surgical Training with VR and AI

Revolutionizing Surgical Training with VR and AI

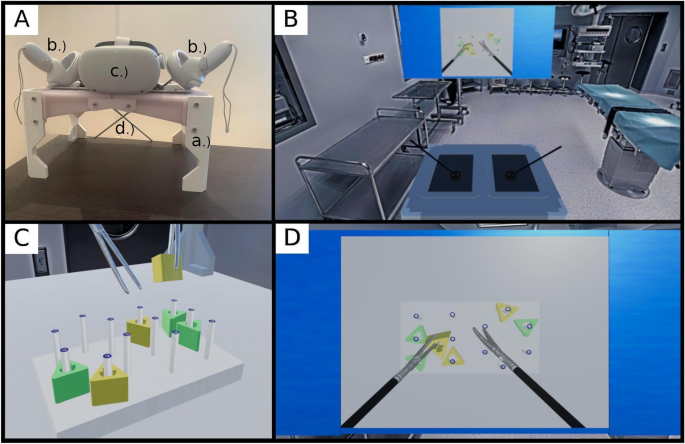

In a groundbreaking study published by Nature, researchers have unveiled a novel approach to surgical training using a low-fidelity virtual reality (VR) simulator enhanced with artificial intelligence (AI) for objective assessment. This pioneering method is poised to transform how medical students acquire laparoscopic skills, offering a cost-effective and efficient alternative to traditional training models.The Evolution of Medical Education

For decades, medical education has relied on high-fidelity simulators, which, while effective, are often expensive and inaccessible to many training centers. The study, led by experts from the University of Pécs, aims to bridge this gap by developing a VR simulator that not only mimics the physical aspects of laparoscopic training but also incorporates AI to provide an objective evaluation of surgical skills.Objective Assessment: A Game Changer

The integration of AI into the VR simulator allows for a more precise and unbiased assessment of students’ performance. By utilizing AI algorithms, the system can detect errors and evaluate the efficiency of surgical tasks, providing detailed feedback that was previously only possible through subjective human evaluation. This advancement addresses a long-standing challenge in simulation-based education, as noted in previous studies by Theodoulou et al. (2018) and Evgeniou & Loizou (2013).Validation and Results

The study involved a cohort of medical students who were randomly assigned to train using either the traditional Fundamentals of Laparoscopic Surgery (FLS) box trainer or the newly developed VR simulator. Results showed no significant difference in the improvement of surgical skills between the two groups, highlighting the VR simulator’s effectiveness. Furthermore, the AI-based assessment proved to be as reliable as human evaluators, significantly reducing the time required for evaluations.Implications for the Future

The successful validation of this VR and AI approach opens the door for wider adoption in medical schools worldwide. It offers a scalable solution that can enhance the accessibility and quality of surgical training, particularly in resource-limited settings. As the demand for distance learning and personalized education grows, this innovative tool could play a crucial role in shaping the future of medical education.

Conclusion

This study highlights the potential of combining VR and AI to revolutionize surgical training. As the medical field continues to evolve, embracing such innovative technologies will be essential in preparing the next generation of surgeons. For more detailed insights, the full study can be accessed at Nature’s website. “`AI and Machine Learning: Revolutionizing the Healthcare Industry

**AI** is already being integrated into **healthcare systems**, from developing new drugs and treatments to diagnosing complex conditions more efficiently and improving access to critical care. This is just the beginning of what **AI** can offer in a medical context.

Benefits of AI in Healthcare

**AI**, which involves using computers to perform tasks that traditionally required human intelligence, is transforming healthcare. When combined with **machine learning**, **AI** can process large datasets to learn and solve complex problems, much like a human would. This technology is being used across various medical fields, including **radiology**, **neurology**, and **emergency response services**, to enhance efficiency and effectiveness.

According to Rohit Chandra, PhD, Cleveland Clinic’s Chief Digital Officer, “AI is no longer just an interesting idea, but it’s being used in a real-life setting.” He highlights that **AI** can now read **MRIs** and **X-rays** with greater accuracy than humans in certain cases, showcasing its advanced capabilities.

AI and Diagnostics

**AI’s role in diagnostics** is particularly promising. For conditions like broken bones, breast cancer, and brain bleeds, accurate diagnosis is crucial. **AI** assists radiologists by acting as a “second pair of eyes,” helping to identify diseases earlier and more accurately. Dr. Po-Hao Chen, a diagnostic radiologist at Cleveland Clinic, explains that **AI** works alongside radiologists to enhance diagnostic performance.

In breast cancer radiology, **AI** has shown significant promise. Dr. Laura Dean, a breast cancer radiologist, notes that **AI** assists in identifying subtle changes in breast tissue patterns, which can be crucial for early detection. Programs like ProFound AI are used to compare mammography images against learned datasets, highlighting areas of concern with a confidence level.

AI in Triage and Patient Management

**AI** is also improving patient care accessibility, especially in emergency situations. For instance, **AI** is used to triage medical cases, prioritizing those most critical. In stroke cases, where every minute counts, **AI** can analyze brain scans rapidly, expediting the care process. Programs like Viz.ai streamline communication among medical professionals, ensuring timely treatment.

The Future of AI in Healthcare

The future of **AI in healthcare** is particularly bright in the realm of research. Dr. Lara Jehi, Cleveland Clinic’s Chief Resource Information Officer, emphasizes the potential of **AI** in generating new knowledge and understanding diseases better. Her work in epilepsy surgery demonstrates how **machine learning** can improve decision-making and treatment outcomes.

As we continue to explore **AI’s possibilities**, ethical and safe use remains paramount. The World Health Organization has issued guidelines to ensure **AI’s responsible integration into healthcare**.

In conclusion, **AI** is poised to transform healthcare, offering unprecedented insights and efficiencies. As **AI technology** advances, it promises to enhance patient care and drive medical research to new heights.

Telemedicine: A Revolution in Healthcare

Telemedicine: A Revolution in Healthcare

In a world where technology is rapidly reshaping every facet of our lives, the healthcare sector is no exception. The recent review published in Cureus delves into the transformative role of telemedicine and telehealth, particularly in public healthcare. This narrative review highlights the integration of telehealth and telemedicine, their historical milestones, and how the COVID-19 pandemic accelerated their adoption.

Historical Milestones and Definitions

Telemedicine, a term coined in the 1970s, literally means “distance healing.” Its roots trace back to the early 1900s with the transmission of electrocardiograms over telephone lines. Fast forward to today, and telehealth encompasses a wide array of services, from video consultations to remote monitoring, making healthcare more accessible than ever before.

Methodologies and Discussions

The review underscores the importance of telemedicine in bridging the gap between healthcare providers and patients, especially in rural areas where access to medical facilities is limited. However, it also acknowledges the challenges, such as regulatory hurdles and infrastructure issues, that must be addressed to fully realize the potential of telehealth.

Benefits and Challenges

Telemedicine offers numerous benefits, including cost-effectiveness, improved access to healthcare, and enhanced emergency preparedness. Yet, challenges remain, such as ensuring patient information security and overcoming technical obstacles in remote areas. The review provides a balanced view, highlighting both the advantages and potential drawbacks of telehealth.

The COVID-19 Pandemic’s Influence

The pandemic has been a catalyst for telemedicine, forcing healthcare systems worldwide to adopt digital solutions quickly. This shift has proven beneficial, particularly for underserved communities, by providing continuous care without the need for physical visits. The review emphasizes the need for ongoing innovation to create user-friendly platforms that cater to both providers and patients.

Recent Technological Advancements

Recent advancements in telehealth technology, such as remote patient monitoring, are paving the way for more comprehensive healthcare solutions. These innovations are crucial, especially as the global population ages, necessitating efficient and cost-effective healthcare delivery.

Conclusion

Telemedicine and telehealth are no longer futuristic concepts but vital components of modern healthcare. As the review suggests, their role in enhancing healthcare access is undeniable, yet challenges persist. Addressing these barriers will be key to unlocking the full potential of telehealth and ensuring equitable healthcare for all.

Future of Construction: Trends Shaping the Industry by 2025

Revolutionizing Construction: Key Trends

The **construction sector** is witnessing a surge in innovative methodologies. Among these, modular construction is gaining momentum for its efficiency and sustainability. By prefabricating components in a controlled environment, developers can drastically cut down on-site construction time, a boon for sectors like multi-family housing and healthcare.

Another game-changer is 3D printing, which allows for the creation of building components layer by layer. This technology is set to revolutionize affordable housing and emergency shelters, offering significant reductions in waste and labor costs.

Technological Integration

The integration of Artificial Intelligence (AI) and Machine Learning (ML) is transforming project management. These technologies enable real-time data analysis, optimizing resource allocation and enhancing safety protocols. By 2025, AI is expected to be a staple in managing construction workflows.

Moreover, advancements in Building Information Modeling (BIM) are pivotal. By linking BIM with IoT devices, stakeholders can gain enhanced control over projects, from design to demolition, fostering unprecedented collaboration.

Sustainability and Smart Technologies

**Sustainability** is no longer a mere trend but a cornerstone of modern construction. The focus is on minimizing environmental impact through eco-friendly materials and energy-efficient systems. Initiatives like zero-carbon projects and recycled materials are becoming standard practice.

Smart building technologies are also at the forefront, with IoT sensors optimizing energy usage and security. As 5G networks expand, these buildings will self-regulate, reducing operational costs.

Challenges and Opportunities

While these advancements offer numerous benefits, they also present challenges. High initial costs, a skills gap, and regulatory hurdles can hinder widespread adoption. Overcoming these barriers is essential for the industry to fully capitalize on these innovations.

Leading the Way

Key players like Skanska and Bouygues Construction are at the forefront, leveraging green building practices and advanced technologies to enhance productivity and sustainability.

As we edge closer to 2025, the **construction industry** is poised for dramatic shifts. Those who embrace these changes will lead the way in shaping a smarter, more sustainable built environment.

The Legislative Battle for Telehealth: Navigating the Future of Virtual Care

As the clock ticks toward a December 31 deadline, a major House subcommittee is considering 15 bills aimed at expanding access to telehealth services. This legislative push is crucial as pandemic-era flexibilities face expiration, potentially affecting countless patients who have come to rely on virtual care.

The American Telemedicine Association has dubbed 2024 the “Super Bowl” of telehealth regulation, advocating for the permanent establishment of Medicare flexibilities introduced during COVID-19. According to FierceHealthcare, this regulatory showdown is critical for the future of telehealth.

The Push for Permanency

Healthcare systems and providers are urging lawmakers to secure permanent Medicare coverage for telehealth services. The absence of legislative action could result in a significant loss of access, particularly for vulnerable populations. Lee Schwamm, M.D., from Yale New Haven Health System, emphasized the need for permanent solutions, stating that telehealth allows for patient-centered care, especially when in-person visits pose challenges.

Prior to the pandemic, telehealth was often a cash-only service, inaccessible to many. However, the integration of virtual and in-person care has become a new standard, as highlighted by Eve Cunningham, M.D., from Providence health system. Telehealth now represents about 20% of ambulatory care visits at Providence, and its services extend to rural and underserved urban areas.

Legislative Proposals